Curbing

Landscape Curbing & Commercial Parking Lot Curbing

Concrete curbing adds to the beauty of the landscape design and acts as an effective root barrier for sod and seeded grasses. It also aids in reducing edging and trimming time. Aside from its practical and functional applications, it can be used to add a distinct look to the exterior of the house.

Our extruded concrete borders, curbing, will add durability and value to any landscape project.

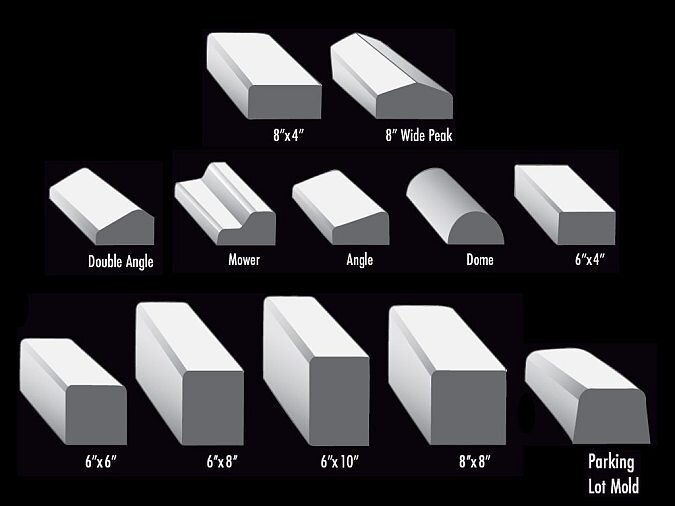

The 5 curbing shapes (6×4, Mower, Angle, Dome & Double Angle) are all 6″ wide at their widest point and 4″ tall at their tallest point.The 8×4, & 8″ Wide Peak are both 8″ wide at their widest point and 4″ tall at their tallest point.

Attractive, permanent landscape accent

More economical and durable than traditional lawn edging

Successful root barrier

Multiple color and design options

Design flexibility including flowing curves, straight lines and custom designs

Reduces edging and trimming time

Most jobs completed in one day

Professional appearance adds value to your property

Existing landscaping not disturbed

Continuous curbing

Commercial curbs, including parking lot curbing

Will not rust like steel, decompose like wood, break like plastic, or move like brick

COLORS FOR YOUR CURBING

Click here to download a PDF of available curbing colors

Base curb color sample:

The base-color of cement determines color range. Like all natural materials, variation is normal in concrete. These are simulations of concrete made with reference Type II gray cement, light tan sand and water to achieve 4″ slump. Actual job-site results may differ.

Cutting Edge Curbing uses Davis Colors, the standard for concrete colors. Through years of experience Cutting Edge Curbing has selected the top 16 colors which will turn out the best for your curbing project. These colors include the most expensive color mixes but as always the color is included in our competitive pricing. The colors selected are 1 lb, 1.5 lb, 2 lb, 3 lb, & 4 lb colors. Our color selection insures that your curbing project and parking lot curbing will turn out as expected.

These digital reproductions are just for ideas. If you choose a color based on this screen or how your printer prints the color chart, you may be in for a big surprise. Please finalize your selection from our printed color card. The color card is a printed piece and there will be a variation in your finished product.

Different types of cement, sand, rock, mixing and job site conditions could alter the finished color. Cutting Edge is consistent and uniform in our methods however, there will be variations which are normal.

It takes approximately 30 days for all the water to evaporate out of the curb and to show the final consistent color. Until then, the curb may look blotchy due to moisture and dew levels in the air.*

Please note: Water must be kept away from the curb for at least 48 hours (72 hours is better) in order to allow curb to cure properly. Premature exposure to water will permanently discolor your curb. If exposed to water prior to the initial 72-hour curing stage your curb will appear blotchy and you risk the appearance of efflorescence on your curb. This discoloration is permanent and is not covered under warranty.

It is important to remember that the color you see on the monitor is a close representation of the color, but not an exact representation of the color as monitors differ from one computer to another. Like all natural materials, variation is normal in the actual concrete whether colored or not.

* Remember to keep sprinklers and drip emitters off 2 days prior to installation and at least 2 days after installation (3 days is better) to allow the concrete to cure naturally and dry to a consistent color. If your curbing gets wet or is in contact with high levels of moisture prior to curing you will get very dark and/or very light areas throughout the project.

Variations in the color of sand obtained from our suppliers in Arizona will also affect the shade of colored concrete as well as the type of cement used in making concrete for extruded landscape borders.

Cutting Edge uses triple washed sand for a more uniform color & the finest quality cement in your concrete border. It costs us more and you can’t tell, but we can. Quality is job #1 with Cutting Edge Curbing.

The base color sample is the natural color of concrete. Great for lots of curbs, especially at the grocery store or the parking lot!

Residential curbing should be more than a concrete ribbon running through your yard. It should blend or contrast with color to emphasize your landscape design.

We can color your concrete curbing to match your landscape look and design.

Your curbing is colored within the main curb concrete mix. Depending on the design and if you are getting the concrete textured you can have multiple colors in the final curbing.

6×10 is only available for Commercial projects. Ask our main office about the minimum charges.

Strength - 3000 psi Compressive 490 psi Flexural

Color - Several colors available

Control Joints - Tooled joints, 3′-4′ on center

Reinforcement - Harbourite 310 1/2 inch polypropylene fibers

Finish - Steel Trowel

Curves - Free-form, as small as 36″ radius

After the path is prepared, rebar dowels are sunken and topped with the plastic guide if “pegging” is required..

Then the rebar is snapped into the guides. The rebar can be bent for curved areas too. Continuous rebar with #3 or #4 is also available without pegging.

The machine is placed on top of the prepared rebar.

And concrete is extruded around the rebar.

The concrete mix envelopes the rebar.

Then we hand finish the extrusion.

And add control joints. # 3 or # 4 Rebar can be added to curb 6×6 or taller.

Question: Do residential customers need rebar in their curbing?

Answer: In almost every case, the answer is no. Rebar in curbing is specified by architects who are concerned about maintaining the integrity of the extrusion should any large vehicles, like a fire engine, drive over the curbing. Or it may be specified when 6×8 or taller curbing is required to hold back an embankment or severe drainage area. It is used in Commercial projects only.

Question: How do I know if I need pegged rebar or just continuous rebar?

Answer: For commercial parking lot curbing jobs, the landscape architect will specify whether or not the rebar needs to be pegged. Continuous rebar helps keep the curbing together should it be broken. Pegging the rebar helps to keep the curb anchored in place.

Note: There is a price difference between continuous and pegged rebar. Price depends on surface pegging into, size of the job, size of the rebar & frequency of pegging.

Application: Rebar cannot be added to 6×4 curb because the curb machine’s plunger would not be able to compact and extrude the material through the mold. With 4″ tall curbing the rebar obstructs and restricts the “plunging action” required for proper machine operation. If 4″ tall curbing is required with rebar, use 6×6 curb and prep the ground so 6×6 curb is 2″ below grade.